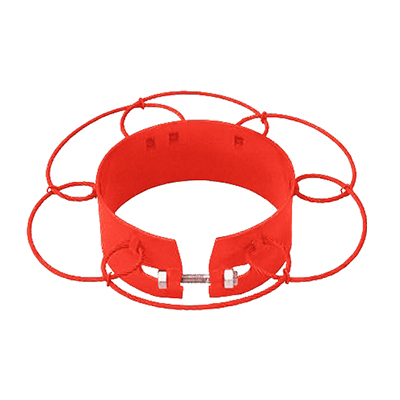

Hinged Bolted Stop Collar

Hinged Bolted Stop Collar is made to latch-on to the casing without having to be slipped over the end of the casing which helps fast and easy installation. No markings or indentations are produced on the casing after installation.

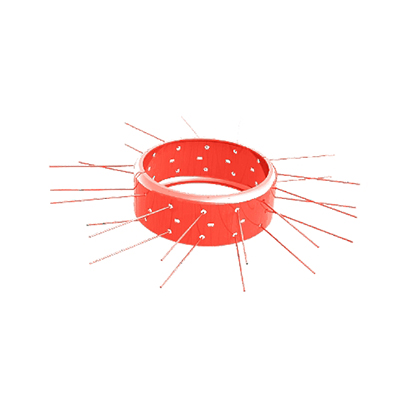

In this design a nut and bolt when tightened draws the stop collar into a friction grip around the circumference of the pipe. The holding force of the Bolted Stop collar is higher than the allowable centralizer starting force.