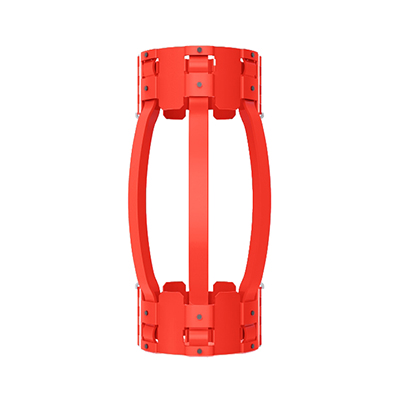

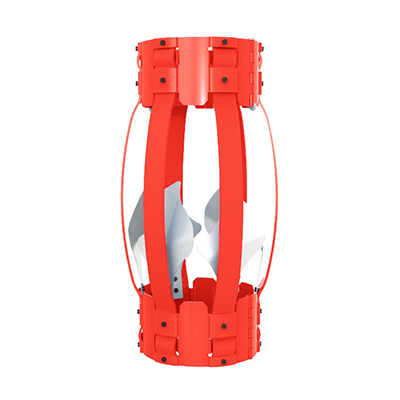

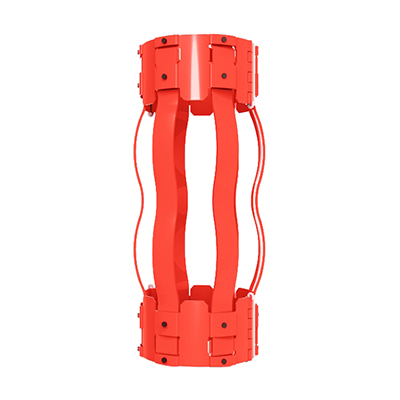

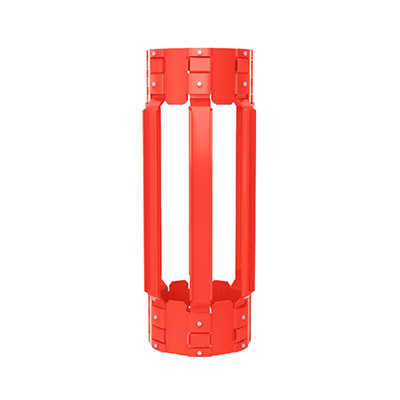

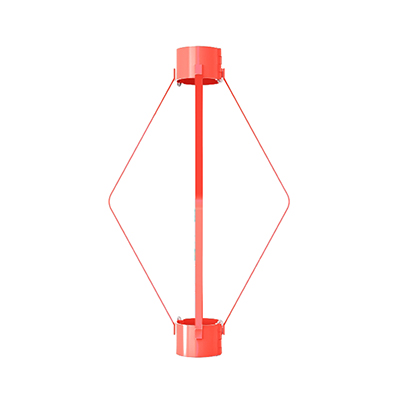

HINGED NON-WELDED BOW SPRING CENTRALIZER

Hinged Non Weld Rigid Centralizers which allow very high fluid passage, are made with a flat-bottom U-profile of different depths. These centralizers can be used for casing as well as tubing applications which need concentric casing strings. It’s structure remove brittle spots and improve durability. These positive centralizers are extremely useful in case of stage and surface cementing. Hinge locking pins are made of high-strength steel for maximum structural strength. Its high performance characteristics are combined with an easy field assembly.

These can be used in combination with Hinged Stop Collar, Hinged Stop Collar with Spiral Nails and few more.