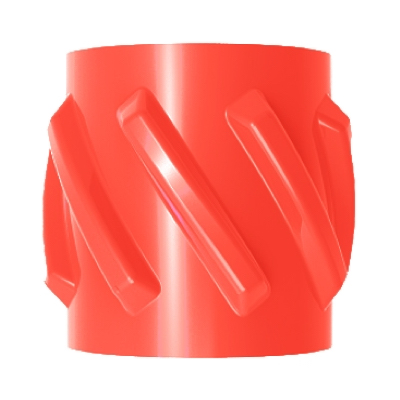

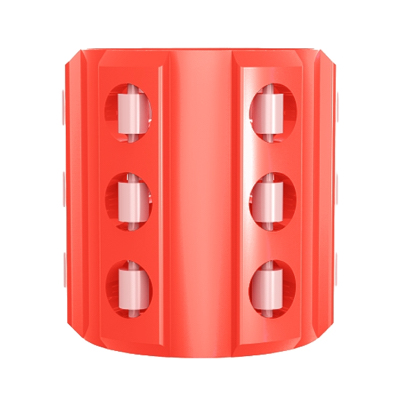

Straight Vane Solid Rigid Centralizer

Straight Vane solid rigid centralizer is designed to provide the right feature to achieve a good primary cementing job with maximum wellbore standoff using suitable functionality. It provide ultimate drag and torque reduction with maximum fluid by pass.

It has high axial load strength. These are available in different material grades. Construction provides superior toughness.