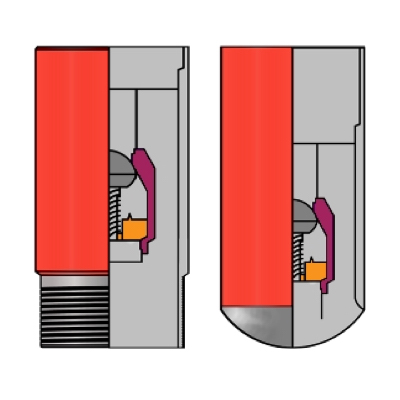

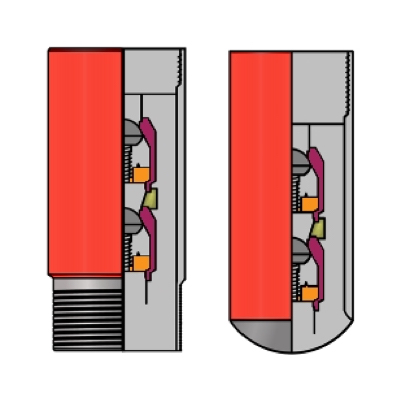

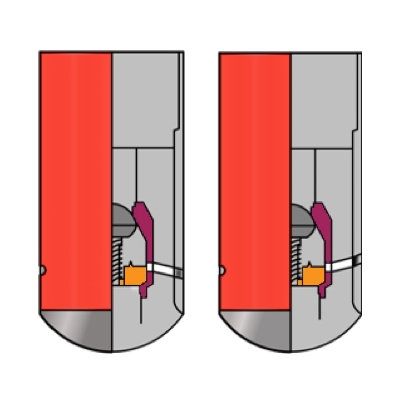

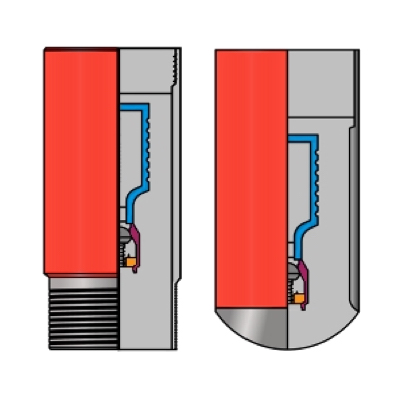

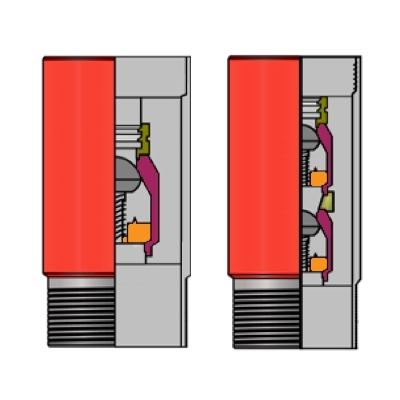

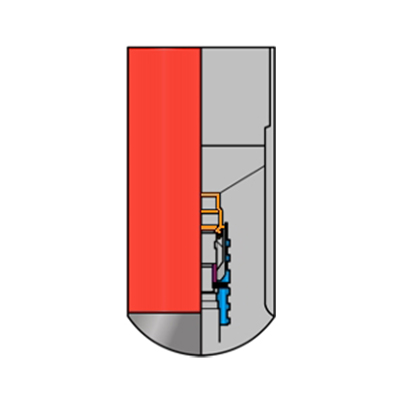

Single Valve Float Collar and Float Shoe

Float equipment are manufactured to match customer's casing specifications. Single Valve Cement Float Collar and Float Shoe offer remarkable performance for all classes of oil and gas wells. The Plunger type valve prevents for cement back-flow.

This design ensures the valve the maximum circulation rate in vertical, horizontal and deviational wells. The material used for float equipment is seamless casing grade steel. All Floats shoes and Float Collars are PDC drillable and valve parts will not damage PDC bits. Provide Fast drill-out & no springs. Available with cement nose, aluminum nose or bladed nose.